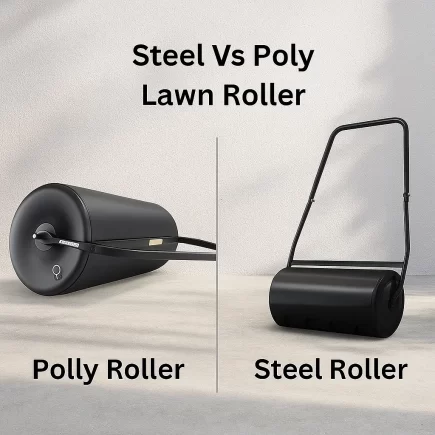

When it comes to maintaining a lush, beautiful lawn, one of the essential tools you’ll need is a lawn roller. This tool is used for leveling uneven terrain, pressing down freshly sowed seeds, and ensuring newly laid sod stays in place while it establishes roots. Lawn rollers come in a variety of materials, but two of the most popular options are steel and poly (polyurethane) rollers.

In this comprehensive article, we will explore the differences between steel and poly lawn rollers, helping you choose the best option based on your specific needs.

Materials Used for Lawn Rollers

Lawn rollers are primarily made from two materials: steel and polyurethane (poly). Both materials have their own benefits and drawbacks, and the one you choose should depend on your unique lawn care requirements.

Steel Rollers

Steel rollers have been around for decades and are known for their durability, strength, and compacting power. For example the 46L Lawn Roller , is made from steel, offering strong performance while avoiding the bulk of traditional heavy-duty models.

Steel is naturally sturdy and holds its shape well even under high pressure. Many high-end or commercial-grade rollers use steel because of its rigidity and ability to handle uneven or sloped terrain.

Polyurethane (Poly) Rollers

Polyurethane lawn rollers are made from a high-density plastic composite that is strong but lightweight. Poly rollers are popular among residential users due to their low maintenance, rust resistance, and ease of use.

They are especially good for small lawns and light rolling tasks, and they are less likely to damage delicate turf during use.

Durability and Performance

Both materials offer adequate durability, but their performance under pressure and exposure can vary significantly.

Steel Rollers: Built for Strength

Steel lawn rollers are ideal for flattening compacted soil, pressing new sod, or repairing ruts left by machinery or weather. Their rigid construction holds up under heavy weight and tough conditions. The painted steel also resists peeling and corrosion, enhancing its lifespan.

Steel’s added weight contributes to better compaction, making it a preferred option for heavy-duty lawn care.

Poly Rollers: Best for Gentle Use

Poly rollers are still strong, but they lack the crushing weight of steel. They’re better suited for light-duty jobs, such as pressing seeds or lightly leveling topsoil. They don’t dent easily, but they may deform under extreme weight or UV exposure over time.

Weight and Maneuverability

One of the most significant differences between steel and poly rollers is their weight. The weight of the roller directly affects how easily it can be maneuvered across your lawn.

Steel Rollers: Compact Powerhouses

Traditional steel rollers are heavy even when empty, sometimes weighing over 100 lbs. However, the steel roller breaks that trend it weighs just 20 lbs empty, making it easier to handle and store.

Once filled with water or sand (up to 46L), it becomes heavy enough to deliver strong compaction but still manageable for one person. This balance makes it perfect for medium-sized lawns that require versatility.

Poly Rollers: Lightweight and Nimble

Poly rollers usually weigh 15-25 lbs empty and up to 100-150 lbs filled, depending on capacity. This makes them easier to maneuver around tight spaces, flower beds, and trees, but they may not compact hard soil as effectively.

Maintenance

Steel Rollers: Rust Protection Required

Steel rollers can rust over time, especially if the paint chips or the roller is stored wet. However, modern steel rollers models come pre-coated with anti-rust paint, drastically reducing upkeep.

Still, you’ll want to:

- Drain the roller after use

- Wipe it dry before storage

- Touch up paint chips periodically

Poly Rollers: Virtually Maintenance-Free

Poly rollers don’t rust and don’t require any painting or protective coating. Their maintenance is as simple as:

- Emptying the contents after use

- Rinsing off dirt or debris

- Storing out of direct sunlight to prevent fading or warping

Storage and Handling

When it comes to storing and handling your lawn roller, poly rollers take the lead due to their lighter weight and compact design.

Steel Rollers

While traditional steel rollers can be bulky and hard to store, but modern compact steel rollers with a fill-up option are easy to store when empty. This makes them far more convenient and user-friendly than older designs.

Poly Rollers

Poly rollers are light, allowing them to be stored upright or laid flat. Their lighter material makes them easy to lift into a storage box or hang on a wall when empty, without any tools or assistance.

Impact on Grass Health

Steel Rollers: While steel rollers provide excellent compaction, they might cause over-compaction on smaller or softer lawns, potentially harming the grass roots and soil structure if used improperly.

Poly Rollers: Poly rollers, being lighter, cause less compaction and are more suitable for delicate lawns. They are better for small or newly sown lawns where excessive weight could damage grass or seedlings.

Choosing between a Poly or Steel Lawn Roller ultimately depends on your specific needs. If you have a large, uneven lawn or need heavy-duty compaction, a steel roller will provide the best results. However, for smaller, flatter lawns, a poly roller offers greater maneuverability and ease of use at a more affordable price.

FAQs

1. Can lawn rollers be used after fertilizing the lawn?

Yes, rolling after fertilizing can help press granules closer to the soil. Just make sure your roller is clean to avoid uneven distribution or chemical staining, especially with steel.

2. How do I know if my lawn needs rolling?

If your lawn feels uneven underfoot, shows signs of frost heaving, or has loose soil after seeding or sodding, it may benefit from rolling. Don’t roll just for appearance.

3. Do lawn rollers work on wet grass?

Lawn rollers can be used on wet grass, but it’s important to avoid over-compaction, which can damage the soil. Poly rollers are lighter and may be a better choice for damp conditions.